- Homepage

- Briquettes REKORD

- Storage briquettes by wholesalers

Storage briquettes by wholesalers

2. Storage instructions trade

2.1 General

The following storage instructions are based on many years of experience in handling lignite briquettes and on the collective knowledge of countless users. These storage instructions are designed to take account of the requirements of preventive fire protection. Compliance with these regulations can also ensure that quality is maintained at optimum levels.

2.2 General storage requirements in the light of preventive fire protection

• Lignite briquettes are flammable. Any contact with naked flames and smoking close to the stored briquettes should therefore be avoided at all costs.

• Do not store lignite briquettes in direct proximity to heat sources or easily inflammable materials.

• Lignite briquettes must be put into storage cooled and free of abrasion.

• Briquette piles and stacks must be accessible from all sides at all times.

• Different sorts of briquette and types of fuel must be stored separately.

• During the storage period lignite briquettes must be checked for a rise in temperature and the formation of condensation.

• There must be consultation with the responsible fire service to ensure that adequate technical fire fighting resources are available (supplies of water for fire fighting including fire water runoffs / hand extinguishers).

Clear signs must be provided (signs "Fire - No naked lights", "No Smoking" / cleanliness).

The following additional information on storage has been compiled based on the product range:

o Storage of briquette packs

o Storage of 10 kg fireplace BB film wrap

o Storage of 10 kg fireplace BB bag

o Storage of loose briquettes H 105, G 156, V 52, GB 182 bulk

o Storage of briquette mix 2nd choice

o Storage of half pallets

2.3 Storage of briquette packs / 10 kg film wrap packs

Strong solar radiation or storage in warm places cause the briquettes to dry out, which then loosens the packaging straps. The quality of the briquettes is badly damaged if they are exposed to the weather (sun, rain) without protection. So-called weather damage is the result.

The following instructions must be noted and implemented for the purposes of fire prevention and the maintenance of optimum levels of briquette quality.

2.3.1 General

• The temperature of briquette packs must be checked during delivery. Only cooled and dry goods may be stacked.

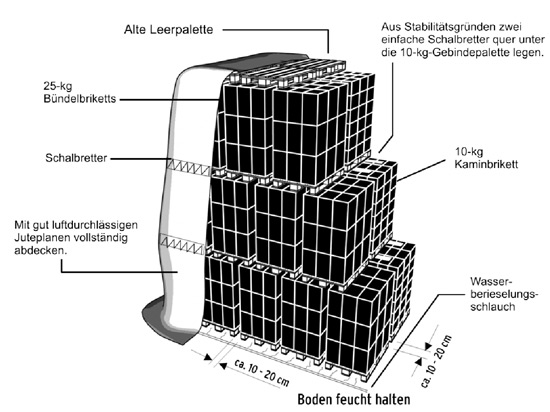

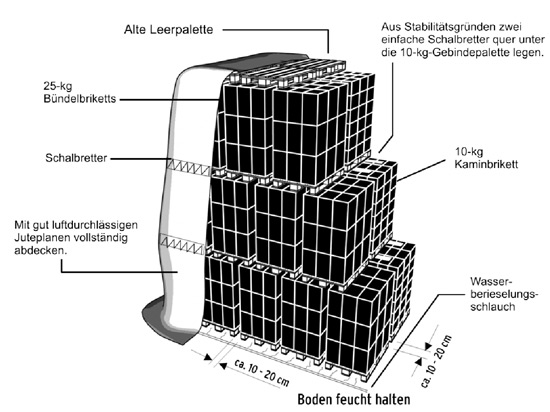

• For reasons of stability the pallets must be stacked in a group on a solid base. The result is a stepped and graduated stack.

• In the interests of fire protection, stability and quality, the height of the stack must be limited to a maximum of four pallets at the retailer.

• The walkways must be suitable for pallet trucks.

• A gap of approx. 20 cm must be left between each pallet row when putting goods into storage.

• A gap of 5 to 10 cm (hand width) must be kept between the pallets in one row.

• A moist storage environment, air moisture > 60 % if possible, must be provided. This is achieved by lightly spraying the ground.

• It is not, however, acceptable to moisten the briquettes directly.

• The storage stack must be accessible from all sides at all times (for fire extinguishing).

• If horizontal liners are inserted to protect the goods, the material used must allow the air to circulate freely between the layers.

• Should moist or heated pallets be detected during checks, these must be removed from the stack immediately and stored separately. The sales partner must be contacted without delay.

• Should, however, the straps around the pallets become slack during correct storage, the vertical strap may be retightened by using a handheld tensioning device (electric or pneumatic). Damaged packs must be replaced during remedial action.

2.3.2 Storage outdoors

• Packs of briquettes stored outdoors must be covered to protect them from atmospheric influences.

• For the purposes of covering, wooden pallets have proved their worth as spacers (Note: Full-surface application Secure grip!).

• The wooden pallets placed on top, as well as the sides, must be covered completely with air permeable tarpaulins. Jute tarpaulins have proved to be very good here (e.g. 425 g/m² jute tarpaulin).

• The jute tarpaulins must be fixed to the sides, e.g. with spacer boards on the Euro pallets.

• A distance of 5 to 6 m must be kept between the stacks (fire break).

• In the interests of fire safety the amount of an individual stack must be limited to around 3,000 pallets.

2.3.3 Storage in halls

• Inflatable halls with fans are inappropriate for storage as extreme airflow helps to dry out the briquettes. This leads to the straps around the packs becoming loose.

The packs are then no longer transportable.

• Good natural circulation of air from top to bottom must be ensured when storing goods in halls.

• Briquettes stored in halls that are open at the sides must be protected from solar radiation (and UV protection).

2.4 Storage of fireplace briquettes – 10 kg bag

10 kg bags are to be stored in the same way as 25 kg packs and film packs. The specifications of section 2 therefore apply. Due attention must also be paid to the following points for paper bags:

• Pallets of 10 kg bags must be stored in halls.

• In the event of high outdoor temperatures:

o arrangements must be made as soon as possible for the interim storage (e.g. preloading) of wrapped pallets of 10 kg bags on enclosed transportation,

o as a rule briquettes must be stored unwrapped.

• It is not permitted to spray the ground and/or the bags, as this will damage the bags.

2.5 Storage of loose lignite briquettes H105/G156/V 52/ GB 182 bulk

Oxygen binds to the surface of fresh carbon. This produces heat, which must be discharged into the environment. If heat builds up as a result of insufficient heat discharge, the temperature of the carbon gradually rises. Under adverse conditions – e.g. strong solar radiation alternating with rain – this effect can cause the carbon to spontaneously combust. The following points must be noted in order to maintain the quality of the briquettes during storage:

• Trucks with no built-in components must be used for pickups ex works. Should trucks with built-in components nevertheless be used, VE-M shall not be responsible for any resulting loss of quality (e.g. due to greater drop height).

• The briquettes must be handled with care when being put into storage. Drop heights above 50 cm must be avoided.

• Only place cooled briquettes into storage.

• Unloading with a gripper damages the briquettes and produces large amounts of abrasion. VE-M shall not be responsible for loss of quality resulting from this.

• Any abraded particles and briquette residues left over from the previous storage must be removed prior to putting new briquettes into storage.

• Storage in covered halls with adequate ventilation is particularly recommended, in order to keep any impairment of quality due to atmospheric influences as low as possible. The weather side must be protected if necessary. Solid hall foundations are ideal with regard to clean product handling.

• In the case of bulk-packaged lignite briquettes, the height of the stack may be max. 5 m.

• If briquettes have to be stored outdoors, it is essential that they are covered with jute tarpaulins to protect them from weather damage. Rubber or plastic tarpaulins must not be used, as these are not air permeable and therefore cause heat accumulation.

• The systematic spraying of jute tarpaulins (several times daily in summer outside temperatures) produces a cool, moist storage environment in the stack of briquettes.

The effect of this is to maintain quality! Damping down the briquettes directly, however, greatly impairs quality and is to be avoided.

• A minimum distance of around 20 cm must be kept between the lignite briquettes and the jute tarpaulin, in order to ensure the necessary air circulation. This is best achieved by using old wooden pallets, which are placed between the briquettes and tarpaulin.

2.6 Storage of briquette mix 2nd choice

Broken briquettes are briquettes of reduced quality. For this reason the following specific instructions apply in addition to the points mentioned above for the storage of loose goods:

• the goods are to be screened prior to storage

• strictly separate storage from other sorts of goods

• a larger number of regular fire safety checks must be carried out

• the maximum stack height is 2 m.

2.7 Abraded particles

Due to their small size, abraded particles are a highly concentrated lignite product, with virtually no heat dissipation. If heat builds up, a gradual rise in temperature occurs. A buildup of heat can be produced in particular by strong solar radiation alternating with rain. This effect can cause the abraded particles to spontaneously combust. The following instructions must therefore be noted:

• only put cooled abraded particles into storage

• the maximum stack height is 2 m

• avoid components leading to heat accumulation

• arrange separate storage (boxes)

• conduct continuous checks

• store smallest possible quantities.

2.8 Extinguishing fires

Should a fire break out, rather than tackle the stack / pile with a full water jet, the seat of the fire must be put out by using a spray jet and wetting agents.

For more information, see the attached document below this article:

Author: Dooffy Design | Viewed: 3926x